SAA – Abbreviation for Colt Single Action Army revolver. The SAA,

as collectors, shooters and engravers, call it, has been in production

since its introduction in 1873. Over the course of its production

countless SAA’s have been engraved both at the Colt factory and by

freelance engravers under contract to the factory and individual

owners. The SAA has also been replicated by a number of companies in

Italy and the US. Overall, the SAA probably accounts for more work for

American engravers than any other make and model of firearm.

|

SCALES – The outer handle plates of a folding knife. Scales can

be made of nearly any solid material but when they are made of metal

they may become the subject of the engraver’s art.

Pictured is a knife made by Steve Hoel and engraved by Steve Lindsay

with a big horn sheep motif and another knife made and engraved by

Steve Lindsay.

|

SCAUPER – British engraver’s term for a flat chisel or graver.

See: FLAT GRAVER.

|

SCENE – A design incorporating more than one figure, sometimes

having a landscape or building in the background and/or foreground.

Also see GAME SCENE,

JAGDSZENEN,

PAESAGGI, SCENE di CACCIA, and

VIGNETTE.

|

SCENE di CACCIA – Italian for game scene. Italian engravers

sometimes refer to paesaggi (literally landscape) for a game scene.

|

SCOPE – See

MICROSCOPE.

|

SCORPER – Archaic American engraver’s term for a flat chisel or

graver. See: FLAT GRAVER.

|

SCRAPER – A hand tool used by engravers to scrape small amounts

of metal while modeling or sculpting a design.

Shown here are pictures of a scraper as made using a Carl Bleile/Lindsay

template.

|

SCRIBER - A tool used by engravers and machinists to scratch a

mark on a hardened surface. The scriber resembles a steel pencil and

has a needle-like point. Also known as a “scratch awl.”

Pictured are examples of three different scribers as used by engravers

and other craftsmen.

|

SCRIMSHANDER – One who scrimshaws.

|

SCRIMSHAW – Scratching or cutting a shallow design into horn,

bone, ivory, or a synthetic representing the aforementioned. Scrimshaw

is done in a style that resembles line, banknote, or bulino style

engraving on metal.

Pictured is a magnification of a Bowie knife handle scrimshawed in the

1970's by Carl B. Bleile of Cincinnati.

|

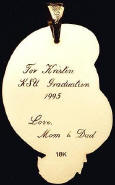

SCRIPT - The script letter group includes script letters,

cursive letters, and swash letters. Each letter style has its

foundation in handwriting. Letters in the script letter grouping are

not used as all caps. Script letters, composed of thick and thin

strokes, have hairlines connecting one letter to another. These

hairlines are also called kerns. Kerns connect letters allowing the

letters to flow into words. Script letters may be basic or formal.

Basic script retains the curvilinear letterform without thick and thin

variations of stroke. The strokes of formal script letters have thick

main stems and thin connectors. Script letters give the impression of

elegance, dignity, and refinement suitable for announcements,

inscriptions, or invitations.

Script lettering is one of the most common types of lettering executed

by hand engravers the others being Blackletter, Gothic, Old English,

and Roman.

Pictured is a hand lettered script inscription by Steve Lindsay.

|

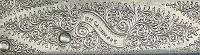

SCROLL – A spiral form in ornamental design derived from the

curves of a loosely rolled parchment scroll. This is the most widely

used and varied type of decoration traditionally engraved into

firearms, edged weapons, jewelry, silverware, armor, and heraldic

insignia. Scrollwork falls into several design categories, the names of

which vary from one country’s engravers to the next.

Pictured are a variety of scroll engravings by various craftsmen

|

SCROLL BANNER – A trade name or owner’s name engraved inside a

curving banner and engraved with scrollwork on the ends.

|

SERIF – The tips engraved at the ends of stems and bars of Roman

letters.

|

SETTING PUNCH - A hand punch used to set precious metal inlays

in place. A setting punch is usually made of brass.

|

SHADE CUTS – In script lettering, the wide cuts as compared to

hairlines. In block lettering, the cut used to shade a filled in

letter.

|

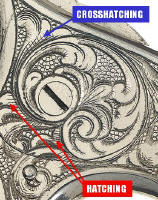

SHADING – A term used by hand engravers that describe the

hatching and/or cross-hatching of the elements of an ornamental design

such as scrollwork. Shading is one of three basic tasks in the

engraving of ornamental designs. These three are: outlining, shading,

and backgrounding. There are styles of engraved ornamentation that omit

either backgrounding and/or shading. For instance sculpted relief

ornament is not shaded as shading is only a substitute for actual

relief. Flare cut scroll requires neither shading nor backgrounding as

the beveled outlining cuts create a relief appearance that contrasts

with a plain background.

|

SHARPENING – The grinding, shaping and polishing of a graver.

Correct sharpening can include: face or rake angle, heel, belly or

relieving facets. Also known as “whetting” or “whetting-up.”

|

SHARPENING FIXTURE – A device used in conjunction with a power

hone for shaping and sharpening gravers to exact, repeatable angles.

Sharpening fixtures may be found in both standard and dual angle

configurations. GRS manufactures the most popular line of sharpening

fixtures used by engravers, jewelers, and stone setters.

Pictured are single angle and double angle sharpening fixtures.

|

SHARPEING TEMPLATE – A polycarbonate plate of various

configurations having a central hole for insertion of a graver holding

clamp, which allows for consistent and repeatable graver sharpening.

Sharpening templates may be used in conjunction with a power hone,

bench stones, or a drill press mandrel for shaping and sharpening

gravers. Sharpening templates are manufactured by Steve Lindsay Tools

and Engraving of Kearney, Nebraska and have been designed by a number

of well known toolmakers and engravers.

http://www.handgravers.com/sharpenin...rallel%20Point

Pictured are a variety of sharpening templates and a univresal template

with a graver in position for sharpening on a bench stone.

|

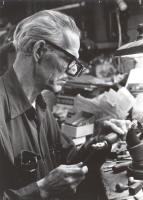

SIDE HAND METHOD – A technique of engraving with hammer and

chisel. Most H&C engravers in Europe and the USA use the European or

“side hand” technique. In the side hand method the engraver holds the

chasing hammer in the strong hand and the chisel in the weak hand with

the palm down with the pointed end of the chisel projecting from the

heel of the hand and the butt of the chisel handle projecting from the

encircling thumb and forefinger. The engraver thus cuts away from his

or her body with the shaft of the chisel roughly parallel with the

forearm. The side hand method can be contrasted with the Asian method

where the engraver cuts with the point of the graver pointed toward

himself and the palm up.

Pictured left is the late Frank Hendricks of San Antonio, Texas

engraving in the "side hand" or "European" method. At right is the late

Floyd Warren of Courtland, Ohio with hammer and chisel engraving "side

hand."

|

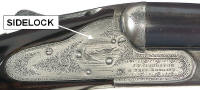

SIDE LOCK – The action mechanism of a firearm assembled on two

separate plates and subsequently placed into opposite sides of a gun

behind the body of the breech. Common to high-grade double guns, the

external portion of the side lock is often the subject of engraved

decoration and thus becomes a focal point of the gun. Also known as a

“lock plate” especially when referring to those fitted with external

hammers.

Pictured examples of side locks are an L. C. Smith (USA), Gebruder

Merkel (Germany), and J. P. Clabrough (England).

|

SIDEPLATE – Usually made of brass or German silver, on muzzle

loading firearms, the sideplate is inlayed into the gunstock opposite

the lock plate and has a hole through which passes the main lock plate

fastening screw. On higher quality arms, the side plate is often

engraved with a decorative motif.

Sideplates are also found on some repeating arms such as Winchester

models 1866 and 1873 and Colt and Smith & Wesson double action

revolvers. In those cases the sideplate protects and allows access to

the lock work of the firearm.

For hinged double barrel cartridge firing arms, see

DUMMY SIDEPLATE.

The pictured examples show modestly engraved sideplates from flint lock

Kentucky rifles. Also pictured is the sideplate of a Uberti replica of

a "66 Winchester engraved by Roger Bleile. In the first picture the

scrollwork has been outlined and the next pictures shows the completed

engraving.

|

SIGNET RINGS- Generally bearing a coat of arms, signet rings are

made by intaglio engraving, Metal signet rings can also be cast, which

is cheaper but yields a weaker material and less fine detail. Signets

are usually engraved by hand engravers who specialize in the field. A

signet is properly engraved in reverse so that when the debossed crest

or coat of arms is pressed into hot wax the resulting embossed seal is

seen in its correct orientation.

The wearing of signet rings (from Latin "signum" meaning sign) is a

longstanding tradition among nobles in European and some other

cultures. Accordingly, the engraving of signets is an ancient branch of

the engravers trade.

In contemporary usage, the signet ring is typically worn on the little

finger of either the right or left hand (depending on the country). The

ring should be worn with the seal facing outwards to enable wax

impressions without removing the ring.

Because it is used to attest the authority of its bearer, the ring has

also been seen as a symbol of his power, which is one explanation for

its inclusion in the regalia of certain monarchies. After the death of

a Pope, the destruction of his signet ring is a prescribed act clearing

the way for the sede vacancy and subsequent election of a new Pope.

Signet rings are also used as souvenir or membership attribute, e.g.

class ring (typically bear the coat of arms or crest of the school), as

an alternative to one with a stone.

The wearing of a signet ring is declining as the European aristocracy

diminishes, however noble families have upheld long standing traditions

of wearing signet rings for centuries. Sometimes the initials of the

individual are engraved into the ring if the person is not of noble

descent and does not have the right to bear [a coat of] arms.

|

SMOKE PULL - A print made by one of several methods from the

engraved surface of an engraver’s work piece. Some pulls appear in

negative, by printing from the top surface, and some in positive by

drawing the ink or lampblack out of the cuts. Today this is usually

accomplished with clear packing or bookbinding tape. The engraver, as a

work record, saves these pulls. Also known as simply as a “pull” or

“smoke print.”

Two "smoke pulls" from the engraved sideplates of a Winchester '73

rifle are shown here.

|

SPAGHETTI ENGRAVING – See

LIBERTY

|

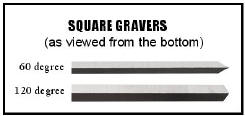

SQUARE GRAVER – So called because the graver blank is square in

cross section. Square gravers are ground and sharpened in such a way

that the cutting point is made from one of the 90 degree corners of the

square and the opposite corner is ground off so that the cutting face

is triangular. The square graver is one of the most commonly used

shapes and is quite versatile because it can be ground in various ways

so that the angle of the triangular cross section is anywhere from 70

to 130 degrees. The square graver should not be confused with the flat

graver whose cutting face resembles that of a wood chisel.

Pictured is a square graver blank, the face profile of a square graver

and a 70 degree square graver next to a 120 degree square graver as

seen from the bottom.

|

SQUARE OFF – To make square the raw end of a cut by engraving a

“pick.”

|

STEMS – Generally applied to the basic cut or fundamental part

of any letter. In block letter engraving, it refers to the vertical

cut.

|

STIPPLE or STIPPLING – A method of creating a texture on

metal using dots or circles. Stippling can be done with a single point

or circle punch, a Vibro-Graver™, or an air powered graver. Stippling

is mainly used as a background treatment for scrollwork and other forms

of leaf based ornamentation.

|

STITCH TOOL – A less common name for a liner or

threader. A parallel line graver.

|

STONE – A rectangular stone used by engravers to sharpen

their gravers. Also known as a bench stone.

Pictured is a hard Arkansas bench stone and a diamond impregnated bench

stone with a graver mounted in a Lindsay template.

|

STONES or FINISHING STONES – Small natural or manmade

stones, either round, square, or triangular in cross section used for

shaping, smoothing, and polishing sculpted engraving in metal.

Finishing stones can be bought in a variety of grits or textures from

rough to very fine which are numbered #150 to #900 respectively.

Sometimes known as ruby stones, Scotch stones or water of Ayer.

|

SUNBURST or SUNRAY MOTIF – Used as decorative space

filler, the sunburst or sunray motif was engraved by 19th century gun

engravers such as L. D. Nimschke.

Pictured is an example of a sunburst motif engraved on an antique

revolver.

|